Tower cranes are essential in construction, lifting heavy materials to great heights. Understanding tower crane parts is crucial for safety and efficiency. Each component plays a specific role in the overall operation.

The main parts include the jib, which extends out to lift materials, and the mast, providing stability. Other essential tower crane parts are the hook, cable, and the operator's cabin. Each element must function correctly to avoid accidents and ensure smooth operation.

These parts can wear down or malfunction over time. Regular checks are necessary to ensure safety. Simple maintenance, like lubricating moving parts, can prevent bigger issues. By understanding these components, teams can improve their project outcomes.

Tower cranes are vital in construction, offering unique capabilities. Their essential components work together to lift heavy loads efficiently. Key parts include the tower, the jib, and the counterweights. The tower provides height and stability. The jib extends outward, allowing the crane to reach far distances. Counterweights balance the load, ensuring safety during operation.

Tips: Regular inspections are crucial. Look for wear and tear in the cables. A small crack could lead to larger issues. Operators should be trained meticulously. Miscommunication can result in accidents, even with experienced crews.

Additional components like the hook and winch are also important. The hook secures loads, while the winch brings them up and down. However, maintaining these parts can be complex. Always keep an eye on the lubrication. Properly done, this can extend the lifecycle of the crane. Yet, it’s easy to overlook and can be a costly mistake.

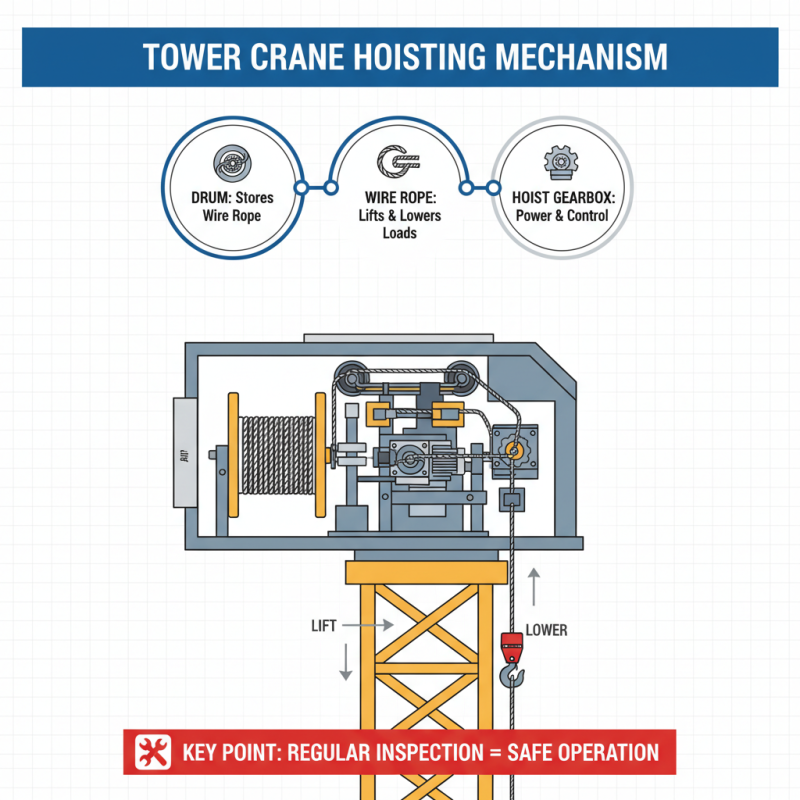

The hoisting mechanism of a tower crane is crucial for its operation. This system consists of several parts, including the drum, wire rope, and hoist gearbox. Each component works together to lift heavy loads efficiently. The drum stores the wire rope that lifts and lowers materials. Regular inspection is vital to ensure safe operation.

Tips: Always check for wear and tear on the wire rope. A worn rope can lead to dangerous situations. Keep the hoist gearbox well-lubricated to prevent friction.

The hoisting mechanism relies heavily on precise engineering. Any misalignment can cause significant issues. Operators must be trained to handle these complexities. Maintaining the hoist's components is essential. Over time, wear can affect lifting capacity.

Tips: Schedule routine maintenance checks. Proper care extends the crane's lifespan. Ensure all operators are familiar with safety protocols. Familiarity can prevent accidents.

The tower crane's base and mast play crucial roles in its overall stability and functionality. The base is typically constructed from reinforced steel. It transfers the weight of the crane to the ground efficiently. A solid base prevents tilting and enhances safety. According to industry reports, a well-designed base can support loads of up to 18 tons, depending on the site conditions.

The mast, on the other hand, provides the necessary height. It consists of vertical columns that can reach impressive heights of over 80 meters. The mast is essential for raising and lowering materials on construction sites. However, it's vital to ensure that the mast is properly anchored to the base. Improper installation can lead to structural failures.

Tips: Always check for wear and tear on mast connections. Use precise measurements during installation for better alignment. Improper alignment can lead to significant problems. Remember, a secure base and mast increase work efficiency. Make sure inspections are routine to avoid future issues. Regular maintenance extends the life of these critical components.

The operator's cabin is a critical part of tower crane operation. It provides the operator with visibility and control. The cabin typically sits at a height of 30 to 200 feet, depending on the crane type. This height allows operators to oversee the entire construction site. However, tall cabins can create challenges for operator comfort and accessibility.

A study by the National Institute for Occupational Safety and Health found that crane operators are at risk for musculoskeletal disorders due to prolonged sitting and poor postures. Proper ergonomics in the cabin design can help mitigate these issues. Operators should have adjustable seating and controls within easy reach.

Tip: Regular breaks can help reduce fatigue in operators. Alternate tasks when possible to keep the operator engaged. The importance of clear communication can't be overstated. Operators rely on ground personnel to relay information. A breakdown in communication can lead to serious mistakes. It's essential for teams to establish clear signals and protocols. Overshadowing these operational aspects are the emotional and psychological factors, such as stress and focus, which can affect performance. Maintaining a negative environment impacts operator efficiency and safety.

This bar chart illustrates the importance of various essential parts of a tower crane, indicating their role in overall operation efficiency.

Safety devices are crucial for tower cranes. They prevent accidents and ensure compliance with regulations. A tower crane operates under various conditions. With heavy loads and heights, stability is key. Safety devices include limit switches and overload indicators.

Limit switches halt the crane at critical points. They provide an essential fail-safe. However, these switches may malfunction. Regular checks are necessary. Overload indicators alert operators when a load exceeds safe limits. This prevents potential disasters, but they can also be misread. Human error can still occur.

Another key device is the anti-collision system. It helps avoid collisions with other structures. Yet, these systems require proper calibration. Improper settings can lead to excess risk on sites. Safety devices in tower cranes must be constantly reviewed. Operators should be diligent. Continuous improvement in safety protocols is vital for all construction professionals.

| Component | Description | Function | Compliance Standards |

|---|---|---|---|

| Load Sensing Device | A device that detects the load weight being lifted. | Prevents overloading the crane and ensures safe operation. | OSHA, ANSI |

| Anti-Two Block Device | Prevents the hook block from coming too close to the crane. | Avoids collision and protects rigging equipment. | OSHA, ASME |

| Emergency Stop Switch | A switch used to immediately halt crane operations. | Ensures quick response to emergencies. | OSHA, ISO |

| Sway Control System | A system that reduces swinging of the load during lift operations. | Enhances load control and safety. | ISO, EN |

| Outriggers | Extendable supports that stabilize the crane. | Prevents tipping during operation. | OSHA, ANSI |