In the dynamic world of construction, understanding the essential Tower Crane Parts is crucial for every construction professional aiming to enhance efficiency and safety on the job site. Tower cranes serve as the backbone of many large-scale projects, providing the necessary height and reach to lift heavy materials with precision. However, to operate these massive machines effectively and safely, it’s imperative to familiarize oneself with their critical components. This guide will delve into the various parts of tower cranes, offering valuable tips that are essential for troubleshooting, maintenance, and optimal operation. Whether you’re a seasoned operator or a newcomer in the construction industry, knowing these components will empower you to make informed decisions and ensure your projects run smoothly. Join us as we explore the intricate details that make tower cranes indispensable tools in modern construction.

Tower cranes are essential in modern construction, providing the height and reach required for various projects. Understanding their key components is vital for any construction professional. At the heart of a tower crane is the mast, which serves as the vertical support structure. The height of the mast can be adjusted to reach desired elevations, making it a flexible choice for varying construction needs.

Tower cranes are essential in modern construction, providing the height and reach required for various projects. Understanding their key components is vital for any construction professional. At the heart of a tower crane is the mast, which serves as the vertical support structure. The height of the mast can be adjusted to reach desired elevations, making it a flexible choice for varying construction needs.

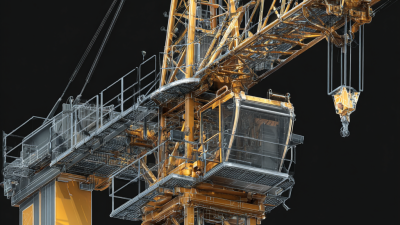

The slewing unit, located at the top of the mast, allows the crane to rotate 360 degrees, giving it the ability to position loads accurately across the construction site. Additionally, the jib, or horizontal arm, extends outward and lifts materials. The jib’s length can significantly influence the crane’s capacity and range. Other critical components include the hoist mechanism, which raises and lowers loads, and the counterweights that ensure stability during operation. Familiarity with these parts not only enhances safety on-site but also improves efficiency in construction practices.

Tower cranes are vital for modern construction, providing the necessary lift and support for large building projects. Understanding the functionality of each part of a tower crane is crucial for construction professionals. At the core of the crane is the mast, which serves as the main vertical structure that provides stability and height. The mast is complemented by the base, which anchors the crane to the ground, ensuring that it remains upright under heavy loads.

Another essential component is the jib, a horizontal arm that extends from the mast and carries the load. The jib’s length can significantly affect the crane's reach and capacity. Attached to the jib is the hoist, which facilitates the lifting and lowering of materials. The hoist is powered by a motor that enables smooth operation, allowing for precise placement of heavy objects. Additionally, the counterweight plays a pivotal role in maintaining balance, ensuring that the crane can operate safely without tipping over during heavy lifts. Understanding these components and their functionalities is key for any construction professional aiming to optimize crane operations and enhance safety on-site.

| Part Name | Functionality | Material | Maintenance Tips |

|---|---|---|---|

| Mast | Provides vertical support for the crane. | Steel | Inspect for signs of rust and structural integrity. |

| Jib | Supports the hoist and provides reach. | Aluminum or Steel | Check for bending or warping. |

| Cab | Houses the operator controls and instruments. | Glass, Steel | Ensure visibility and check window seals. |

| Winch | Lifts and lowers the load. | Steel | Lubricate regularly and check for cable wear. |

| Counterweight | Balances the crane when lifting loads. | Concrete or Steel | Check for cracks and secure mounting. |

When it comes to tower cranes, safety is paramount. Construction professionals should be well-versed in the essential safety features that come standard with these towering machines. One of the most critical components is the overload limit switch, which prevents the crane from lifting loads that exceed its maximum capacity. This feature significantly reduces the risk of accidents due to overloading, ensuring that the crane operates within safe parameters.

Another vital safety feature is the anti-collision system, which helps prevent accidents between multiple cranes or other structures on the site. These systems typically use sensors and cameras to monitor the crane's environment and provide alerts to the operator if any potential collisions are imminent. Additionally, the emergency stop system is crucial for immediate shutdown in case of unforeseen problems. By understanding and regularly checking these safety features, construction professionals can enhance safety protocols and contribute to a more secure working environment when operating tower cranes.

Maintaining tower cranes is crucial for ensuring their longevity and optimal performance on construction sites. Regular inspections and maintenance routines can prevent common issues, saving time and reducing operational costs. Key components such as hoists, pulleys, and hooks should be checked for wear and tear. It's also essential to lubricate moving parts regularly and inspect electrical systems to avoid malfunctions. Proper maintenance not only extends the lifespan of the crane but also enhances safety for the operators and workers on site.

As the Indian construction sector continues to grow, crane manufacturers are evolving to meet the demands of this booming industry. With advances in technology and design, cranes are becoming more efficient and user-friendly. Companies are focusing on providing training for operators and implementing innovative maintenance solutions that ensure equipment stays in peak condition. By prioritizing maintenance and investing in quality parts, construction professionals can ensure that their tower cranes are reliable, contributing to the overall success of their projects in this dynamic market.

Selecting the right tower crane parts is crucial for ensuring the efficiency and safety of any construction project. Every project has unique requirements that dictate the size, capacity, and capabilities of the crane being used. When evaluating parts, professionals should consider factors such as load capacity, maximum reach, and the height of the building being constructed. Each part, from the crane's mast to the hook and winch, plays a pivotal role in the overall functionality of the crane, influencing how effectively it can manage materials and navigate the job site.

Additionally, collaborating with tower crane manufacturers can provide valuable insights into the latest technological advancements in crane components. Features like automatic load-moment indicators and advanced control systems are essential for enhancing safety and operational efficiency. Ensuring compatibility among all crane parts also minimizes the risk of malfunctions and maximizes productivity. By prioritizing quality and suitability when selecting tower crane parts, construction professionals can significantly improve their project's outcomes.