The effectiveness of construction processes heavily relies on the performance and maintenance of equipment, particularly tower cranes. Tower Crane Parts are vital components that determine the operational efficiency and safety of these towering machines. According to a report by Research and Markets, the global tower crane market is expected to grow significantly, driven by an increase in infrastructure development and construction activities. Effective maintenance and timely replacement of tower crane parts not only enhance the lifespan of the machinery but also reduce downtime, which can cost construction companies thousands of dollars. In fact, a study from the International Journal of Construction Management highlights that a well-maintained crane can improve productivity by up to 20%. Therefore, understanding how to effectively maintain and replace these essential parts is crucial for optimal performance, ensuring that projects are completed on time and within budget.

The effectiveness of construction processes heavily relies on the performance and maintenance of equipment, particularly tower cranes. Tower Crane Parts are vital components that determine the operational efficiency and safety of these towering machines. According to a report by Research and Markets, the global tower crane market is expected to grow significantly, driven by an increase in infrastructure development and construction activities. Effective maintenance and timely replacement of tower crane parts not only enhance the lifespan of the machinery but also reduce downtime, which can cost construction companies thousands of dollars. In fact, a study from the International Journal of Construction Management highlights that a well-maintained crane can improve productivity by up to 20%. Therefore, understanding how to effectively maintain and replace these essential parts is crucial for optimal performance, ensuring that projects are completed on time and within budget.

Scheduling regular maintenance for tower crane parts is essential to ensure optimal performance and safety on construction sites. According to a report by the Occupational Safety and Health Administration (OSHA), improper maintenance accounts for around 12% of all crane-related accidents. This underscores the critical importance of adhering to proactive maintenance schedules. Best practices suggest that maintenance should ideally be conducted every 500-1,000 operating hours, depending on the specific model and usage conditions. Keeping a log of maintenance activities can help track the frequency and type of maintenance performed.

Incorporating predictive maintenance techniques can also enhance the efficiency of maintenance scheduling. The National Institute for Occupational Safety and Health (NIOSH) states that predictive maintenance allows for the identification of potential failures before they occur, reducing downtime by up to 30%. Utilizing technologies such as vibration analysis and thermal imaging can help detect wear and tear on crane parts early, allowing for timely replacements. By implementing these best practices, contractors can significantly reduce the risk of equipment failure and prolong the lifespan of their tower cranes, ultimately leading to safer construction environments and reduced costs.

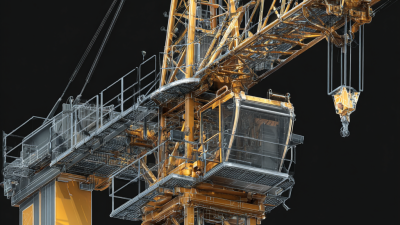

Understanding the lifespan of essential tower crane components is crucial for optimal performance on construction sites. Tower cranes endure significant wear and tear due to their exposure to various weather conditions and the heavy loads they handle. Regular assessments and maintenance of parts such as the tower sections, jib, and hoist mechanisms are vital not only for safety but also for prolonging the operational life of the crane. Notably, parts that are more susceptible to corrosion, like those exposed to moisture and chemicals, should receive particular attention.

Tips for maintenance include implementing a consistent inspection schedule where all essential components are evaluated for signs of wear. Ensuring that lubrication is applied regularly to moving parts can prevent overheating and failure. Furthermore, replacing parts before they reach the end of their lifespan can save costs in the long run, as it minimizes the risk of more extensive damage to the crane.

With advancements in technology, more cranes are being designed with replaceable components that can be easily updated or refurbished, extending their overall lifespan. For example, reusing parts from decommissioned cranes can be a cost-effective option that adds value to the maintenance process while supporting sustainability efforts within the construction industry.

In recent years, the construction industry has witnessed a significant shift towards the integration of advanced technology for optimizing tower crane performance and maintenance. The use of IoT-enabled sensors and monitoring systems has transformed how crane operators and project managers assess the condition of crane parts. According to a report by the Global Construction & Infrastructure Market, the adoption of such technologies can reduce unexpected equipment failures by approximately 20%, leading to substantial cost savings and improved operational efficiency.

In recent years, the construction industry has witnessed a significant shift towards the integration of advanced technology for optimizing tower crane performance and maintenance. The use of IoT-enabled sensors and monitoring systems has transformed how crane operators and project managers assess the condition of crane parts. According to a report by the Global Construction & Infrastructure Market, the adoption of such technologies can reduce unexpected equipment failures by approximately 20%, leading to substantial cost savings and improved operational efficiency.

Advanced monitoring systems provide real-time data on critical parameters such as load capacity, wind speed, and crane movement. This information not only aids in proactive maintenance but also helps crews adhere to safety protocols, minimizing downtime. The International Journal of Construction Management highlights that projects employing these technologies have seen a 15% increase in productivity, largely due to the enhanced decision-making facilitated by accurate data collection and analysis. By investing in cutting-edge technology, companies can ensure their tower cranes operate at optimal performance levels, reducing the frequency of part replacements while maximizing their equipment lifespan.

When it comes to maintaining tower cranes, understanding the financial implications of preventative maintenance versus reactive repairs is crucial.

Preventative maintenance involves regular inspections and servicing, which, although it may incur upfront costs, can save significant amounts in the long run.

By addressing potential issues before they become serious problems, companies can avoid the steep expenses associated with emergency repairs and downtime.

Tips for maintaining tower crane parts effectively include creating a detailed maintenance schedule and adhering to it rigorously.

Regular checks on vital components such as cables, hooks, and braking systems can help identify wear and tear early.

Additionally, incorporating technology, such as digital monitoring systems, can provide real-time data on crane conditions, allowing for timely interventions.

On the other hand, while reactive repairs may seem to save money initially, they often lead to unexpected costs and prolonged downtime.

It's essential to factor in not only the repair expenses but also the potential loss in productivity.

Investing in a robust maintenance plan is ultimately more cost-effective, ensuring that tower cranes operate at optimal performance and enhancing overall project efficiency.

When it comes to maintaining tower cranes, understanding the key indicators for part replacement is vital for ensuring efficiency and safety on the job site. One significant sign that a component may need replacing is visible wear or damage. Regularly inspecting the crane's cables, hooks, and gears for fraying or cracks can prevent potential failures that could lead to downtime or accidents. Additionally, monitoring the performance of these parts during operation can provide insights; decreased functionality, such as slower movements or increased noise levels, often signal that maintenance or replacement is necessary.

To further enhance your maintenance routine, keep track of the operational time of crucial components. Each part has a recommended service life, and exceeding this timeframe can increase the risk of failure. Implementing a log for maintenance checks can help you stay proactive.

Tips: Always use genuine replacement parts as they ensure compatibility and reliability. Engage trained personnel for inspections—experience matters significantly when diagnosing potential issues. Lastly, prioritize regular training for your team on the latest maintenance techniques and technologies to keep everyone updated on best practices.